Power Steering

Power Steering

“The power steering system is the advanced steering system in

which the effort required to steer the front wheels of the vehicle

side to side is reduced by using intermediate electric or hydraulic

devices that multiplies the force applied by the driver through

steering wheel in order to achieve smooth and quick directional

change of the vehicle.”

History of Power Steering System

According to the legend advanced by a serious publication on the history of automobile steering systems, a man by the name of Fitts installed a power steering system on an antique car in 1876. Robert E. Twiford, an American from Pennsylvania, patented the first all-wheel drive system on April 3, 1900, and his patent included a power steering system.

Francis W. Davis, an engineering in the Heavy Vehicles division at Pierce-Arrow, invented a concept similar to the one used today in 1926. He offered it to GM, but they determined that it would be too expensive to make and include in mass-market vehicles.

Interest in power steering increased during World War II, as it facilitated maneuvers for large military vehicles.

In 1951, Chrysler released the Imperial, a vehicle equipped with power steering.

Needs of Power Steering

1. Quick response- As the number of the vehicle on the road is increasing day by day and today almost 60% families of the world are having a 4 wheeler in their houses, with this increase in number of vehicles the danger of accidents on road is also increased, so to avoid this danger and to take quick turns required by the road conditions a quick response steering system is required in a 4 wheel vehicle.

2. Steering efforts – If we drive old cars like Maruti Suzuki 800 , it is found that the steering wheel of the car feels very hard to rotate when the vehicle is going below 40 km/hr (above that the steering feels less hard) which is found to cause fatigue to the driver while going on a long ride. So a vehicle should be equipped with a power steering system so that the steering effort required to steer the front wheels can be reduced.

3. Bump steer- As we know the bumps of the road is reduced by the suspension system but as the steering system is directly attached to the wheel’s hub some amount of bumps force is also transferred to the steering system which in turn tries to steer the vehicle against the will of the driver due to which a vehicle can lose its stability, though the bump steer can be controlled mechanically by providing optimum scrub radius (angle between the centre line of the wheel and the king-pin inclination of the knuckle) but the power steering controls it in a more effective manner.

4. Return ability- after taking a turn it is found that the steering returns automatically to its original position which in turn automatically straightens the moving vehicle. A vehicle equipped with a power steering system provides better return ability to the steering system.

Components of Power Steering

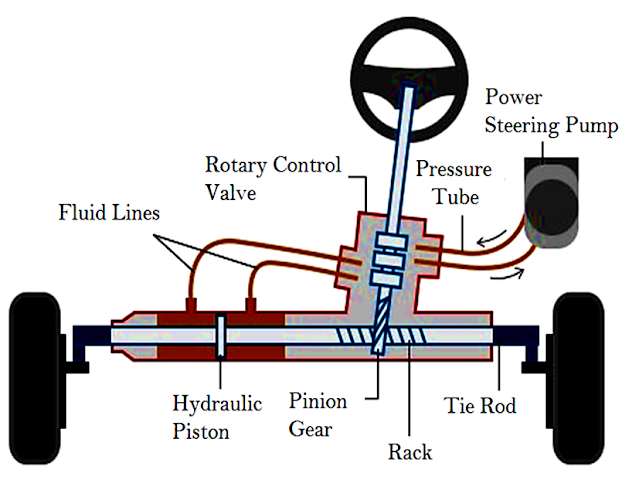

1. Steering mechanism- Usually rack and pinion steering mechanism is used in power steering in which the rotational motion of the steering wheel is converted into the transverse motion of the wheels by a set of constantly meshed worm gears called rack that provide transverse motion and a pinion that provides rotational motion.

2. Linkages – They are the mechanical constraints that provide relative motion between two components, the type of linkages used in power steering is the tie-roads that connects the rack to the knuckle of the wheel in order to transfer the transverse motion of the rack to the wheels.

3. Power device- A force multiplying device (either hydraulic or hybrid or electric) is used to multiply the steering wheel force in order to reduce steering efforts. This device is attached with the pinion of the rack and pinion mechanism.

4. Steering wheel- A round steering wheel is used inside a cockpit (operated by the driver) that provides the rotational steering input to the further steering devices in order to steer the vehicle.

Types of power steering system

1. Hydraulic power steering system

2. Electro – hydraulic power steering system

3. Electronic power steering system

1. Hydraulic power steering system

It is the type of

power steering system in which hydraulic system having

hydraulic pump driven by the engine and hydraulic

cylinders, is used to multiply the steering wheel input

force which in turn reduces the efforts required to steer

the front wheels of the vehicle.

A highly compressed hydraulic fluid is used inside the

hydraulic cylinder that applies pressure on the steering

gear.

Working

When the driver provides input by rotating the steering wheel, the hydraulic pump driven by the engine starts pumping the highly compressed hydraulic fluid through lines. The hydraulic pressure produced by the pump enters the hydraulic cylinder which in turn applies pressure over the cylinder’s piston. The piston which is under high pressure starts moving from one end to the another which in turn pushes the further fluid through lines, with this movement of piston the input force applied by the driver is multiplied several times. This high pressure fluid sent by the hydraulic cylinder then applies the pressure to the attached pinion through the coupling mechanism which in turn applies high force to the rack gear and the steering action in the front wheels takes place.

2. Electro – hydraulic power steering system

It is the modified version of the hydraulic system in which

the rotary hydraulic pump which is driven by the engine

in hydraulic power steering system is replaced with the

hydraulic pump which is driven by the electric motor.

It is also called the hybrid power steering system due to

the use of both hydraulic and electric components.

3. Electronic power steering system

It is the latest type

of power steering system in which the hydraulic system

from the hydraulic power steering is completely replaced

with electric motors and electric sensors, instead of using

hydraulic force ,the motor driven by the vehicle’s battery is

used to apply force on the steering gear and torque

provided by the motor is controlled by the sensors that

detects the position of the steering column.

The steering response of this system is quick and very

effective that is why it is used in almost all the new cars

today.

Comments

Post a Comment