TQM TOOLS & TECHNIQUES

TQM TOOLS & TECHNIQUES

Statics is defined as

the science that deals with the collection, tabulation, analysis,

interpretation & presentation of quantitative data.

statistical

techniques are applicable in all situations where quantification is possible. Example- Engineering, commerce, industry, trade, economics, life

science, earth science, physical science, medical science etc.

Data Vs Information

Data |

Information |

|

Data is raw, unorganized facts

that need to be processed. Data can be something simple and seemingly random

and useless until it is organized.

|

When data is processed,

organized, structured or presented in a given context so as to make it

useful, it is called information.

|

|

Example-Each

student's test score is one piece of data.

|

Example-The

average score of a class or of the entire school is information that can be

derived from the given data.

|

Types of data-

1. Attribute

data-

The data obtained by

counting are called discrete (or attributes) data. It’s has two types Yes/no

types & Counting types. It’s very simple to collect as compared to variable

data. Example- Mail deliver- it’s on time or not on time? Phone answer, product

confirmation Number of students pass in class? etc.

2. Variable

data-

The data obtained by

actual measurement are continuous (or variable data). Example Sampling

inspection plan we are taking one sample out of 10 parts & check the weight

of it. so the reading should be digit or in number are variable like 250, 255,

248 grams etc.

Measures of Central

Tendency: -

A

measure of central tendency is a summary statistic that represents the center

point or typical value of a dataset. These measures indicate where most values

in a distribution fall and are also referred to as the central location of a distribution.

In statistics, the three most common measures of central tendency

are the mean, median, and mode.

1. Mean-The mean is also called arithmetic average, is the sum of the observations divided by numbers of

observations.

2. Median-The median is the middle value. if data contains an

odd numbers of items, the median item of the array. if there is an even number

of items, it’s the arithmetic mean of two middle numbers.

To

find median-

If there are ‘n’ observations of the variant& they

are arranged in ascending order, then median is given by (n+1)/2 value if ‘n’ is odd.

If ‘n’ is even then median is taken average of (n/2) or (n/2 +1).

3. Mode-the mode is most commonly occurring value. it’s defined as “The valve

of the variable which occurs most frequently i.e., the value of maximum

frequency.

Measure of Dispersion or Measure of Precision-

The spread of observations around the Centre is known as

dispersion. There are three measure of dispersion-

1. Range-It’s

defined as the difference between the highest & lowest observations.

Mathematically Mean

R = Xh-Xl

Where R= Range

Xh = Highest observation value

Xl = Lowest observation value

2. Mean deviation-The

mean deviation is the mean of absolute difference of the values from the mean,

median or mode.

Mean Deviation

Where A= Mean or mode or median of observations.

3. Standard Deviation-It’s measure of spread of data. Standard deviation is compute as

the square root of the mean of the squares of the difference of variate values

from their mean.

Where S= Standard

deviation

Xi= Observed

values

N = Number of observed

values

Control Chart-

A control chart is a

graph that displays data taken over time & the variations of data. It’s a

tool to distinguish between chance & assignable causes of variations in a

process.

The controlled chart is

used to check whether the process is controlled statically or not. The main

objective of using control chart is to determine when a process is

out-of-control so that necessary action may be taken.

Types of control chart-

There

are two basic types of control chart

1. Control Chart for Variables-

It’s measurement of quality characteristic of interest. The most commonly used variable control charts are-

1. X Bar or Average chart- It’s

used to monitor the centering of process to control its accuracy.

2. R or Range chart-

It’s monitor the dispersion or precision of the process.

3. S or Standard Chart-

It’s shows the variation of process.

2. Control Chart for Attributes –

It’s required a determination of whether a part is defective or

how many defects are there in a sample.

1. P-Chart- The chart for fraction

rejected as non-conforming to specifications.

2. NP- Chart – The control chart for

number of non-conducting items.

3. C-Chart- The control chart for

number of non-conformities.

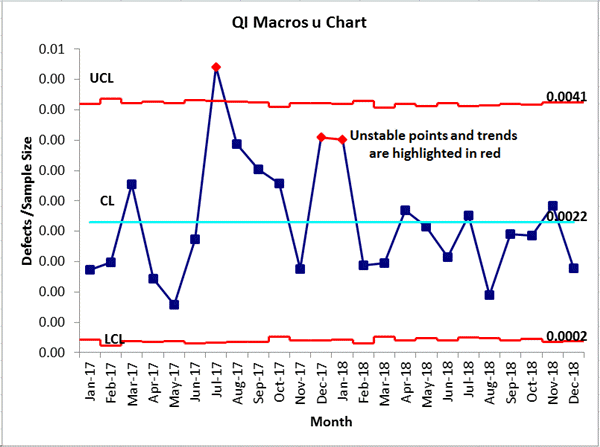

4. U-Chart- The control chart for

number on non-conformities per unit.

Comments

Post a Comment