Differential

Differential

“Differential is the mechanism by means of which outer wheel

run faster than the inner wheel while taking the turn or moving

over upheaval road”

Differential is the part of inner axle housing assembly,

which include the differential, rear axles & bearings. In the

differential gear arranged in such a way that connects the

propeller shaft with the rear axles.

Differential are used in rear drive axle of front engine, rear

wheel drive vehicles & also used in the transaxles on front

engine, front wheel drive wheels.

History

There are many claims to the invention of the differential gear, but it is possible that it was known, at least in some places, in ancient times. Confirmed historical milestones of the differential include:

100 BC–70 BC: The Antikythera mechanism has been dated to this period. It was discovered in 1902 on a shipwreck by sponge divers, and modern research suggests that it used a differential gear to determine the angle between the ecliptic positions of the Sun and Moon, and thus the phase of the Moon.

250 AD: Chinese engineer Ma Jun creates the first well-documented south-pointing chariot, a precursor to the compass that uses differential gears to discern direction rather than a magnet.

1720: Joseph Williamson uses a differential gear in a clock.

1810: Rudolph Ackermann of Germany invents a four-wheel steering system for carriages, which some later writers mistakenly report as a differential.

1827: Modern automotive differential patented by watchmaker Onésiphore Pecqueur (1792–1852) of the Conservatoire National des Arts et Métiers in France for use on a steam wagon.

1832: Richard Roberts of England patents "gear of compensation", a differential for road locomotives.

1874: Aveling and Porter of Rochester, Kent list a crane locomotive in their catalogue fitted with their patent differential gear on the rear axle.

1876: James Starley of Coventry invents chain-drive differential for use on bicycles; invention later used on automobiles by Karl Benz.

1897: first use of differential on an Australian steam car by David Shearer.

1958: Vernon Gleasman patents the Torsen dual-drive differential, a type of limited-slip differential that relies solely on the action of gearing, instead of a combination of clutches and gears.

Functions of Differential

1. It transfers the power from the drive shaft to all the wheels.

2. It provides a final reduction in gear.

3. It splits the amount of torque that is going to each of the wheels.

4. It allows the wheels to rotate and spin at various speeds during turns.

Parts of Differential

1. Pinion Drive Gear: This part transfers the power to the ring gear from the drive shaft.

2. Differential case assembly: This part holds the Ring gear along with other components which drive the rear drive axle.

3. Ring Gear: This section transfers the power to the previous part that is Differential case assembly.

4. Rear drive axles: These are the steel shafts which transfer the torque from differential case assembly to drive wheels.

5. Axle housing: These are the metal body that encloses the rear axles and also supports the rear axle assembly.

6. Rear axle bearings: These are the ball bearings which fit between the axle housing and the axles.

7. Side gears: These gears help both the wheels to turn independently while turning.

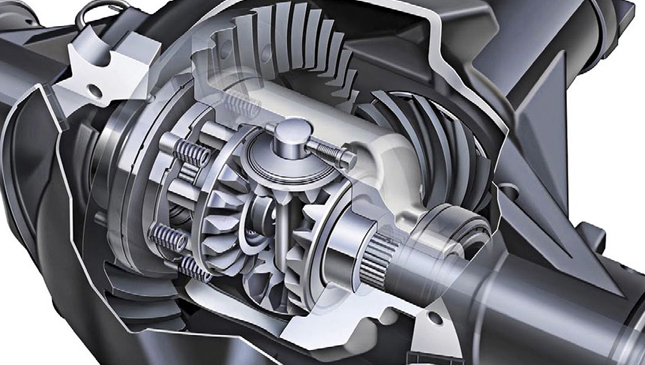

Construction of Differential

In the differential, Bevel pinion gear is fixed to the

propeller shaft which rotates the crown wheel. The Crown wheel has another unit called the Differential

unit. It consists of two bevel gears (Sun gear) and two

bevel gears (Planet gear). The bevel gears are in contact with the Half shaft of the

rear axle. When the crown wheel is rotating, it rotates

the differential unit. The bevel (sun) gears of the

differential rotate the two shafts.

Working of Differential

When the car is on a straight road, the ring gear,

differential case, differential pinion gears, and two

differential side gears all turn as a unit. The two differential pinion gears do not rotate on the

pinion shaft. This is because they exert equal force on

the two differential side gears. As a result the side

gears turn at the same speed as the ring gear, which

causes both drive wheels to turn at the same speed

also. However, when the car begins to round a curve, the

differential pinion gears rotate on the pinion shaft.

This permits the outer wheel to turn faster than the

inner wheel.

There are 4-types of differentials use in automobiles.

1. Open Differential

An open differential (OD) is the most common type. It is also the least expensive. An open differential allows the vehicle to go around corners without dragging the outside wheel. However, power is transferred to the wheel with the least amount of traction (grip on the road). If that wheel is on ice or other slippery surfaces, the vehicle will not move forward and the wheel with the power will simply spin. In vehicles with two-wheel drive, if they have an open differential in effect they have only a single drive wheel. In four-wheel drive vehicles using open differentials (usually standard from the factory), only one wheel on each axle powers the vehicle. Advantages include seldom breaking an axle, less tire wear, and they are free as most new vehicles come with open differentials.

2. Limited-Slip Differential

Under ideal road conditions, a limited-slip diff acts just like an open differential and transfers torque independently to each wheel. But, under hard cornering or heavy acceleration where an open differential would generally cause a tire to slip, a limited-slip differential prevents the normal amount of torque to go to the slipping tire (the one with least resistance). The LSD using a series of clutches (called a clutch pack) & it's allows limited wheel slippage while maintaining power to both drive wheels. LSDs are popular in race cars, as there are often times when they are coming out of turns and need to accelerate without losing power to one drive wheel.

3. Locking Differential

Locking differentials use clutches and springs to activate a lock which sends an equal amount of power to each wheel no matter the traction situation. This essentially creates a fixed axle. The advantage is that both wheels have power at all times. The disadvantage is that turning is much more difficult since both wheels must turn at the same rpms. So most lockers must be disengaged when making sharp turns. Lockers can also present the driver with some dangerous situations.

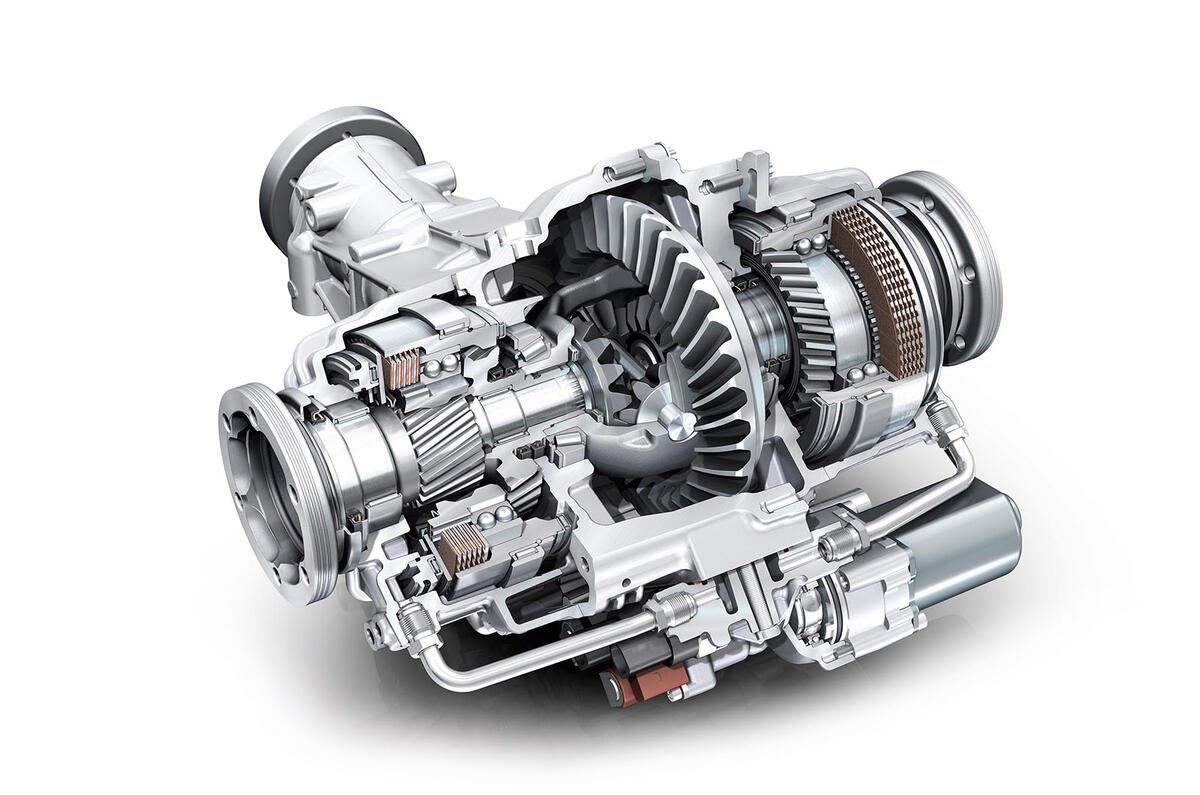

4. Torque Vectoring Differential

The most complicated and advanced type of differential, a torque-vectoring differential uses a collection of sensors and electronics to obtain data from various things (road surface, throttle position, steering system, etc.) to activate electronically actuated clutches and a controller.

Also known as active differentials, they work in the most efficient way which results in a truly dynamic, high performance driving experience. Torque-vectoring differentials can be found in some high performance rear-wheel drive and all-wheel drive vehicles.

Application of Differential

1. Cars

2. Buses

3. Trucks

4. Three wheelers

5. E-Rickshaw etc.

Troubleshooting in Deferential : Troubles, Causes & Remedies

1. Gear Noise

- Insufficient lubricating oils : Replenish with correct amount.

- Low viscosity, poor quality oil : Replace with correct quality oils.

- Wrong adjustment of drive pinion & Ring gears : Adjust properly.

- Improper tooth contact in mesh between drive pinion & ring gears : Adjust or Replace.

2. Bearing Noise

- Damaged or Worm bearings or Worm parts : Replace

- Broken Barings on axles shafts :Replace

- Damage bearings of rear drive pinion : Replace

3. Vehicle does not move when put in gears

- Broken teeth of crown wheel & Pinion : Replace

- Broken cross or star pinion : Replace

- Broken flange key : Replace

- Broken Propeller Shaft : Replace

- Broken Axle Shaft : Replace

Comments

Post a Comment