Wheel & Tyre Assembly

Wheel & Tyre Assembly

Wheel

“The wheel assembly consists of the hub, disc or spokes, rim, tyre &

tube.”

Wheels is the important part of the vehicle. The vehicle

can’t move on the road without wheels. “The wheels are legs

of the vehicle carry it to far off distance. The support of the

whole weight of the vehicle & convert rotary motion into

longitudinal one.”

The wheel also resists side force created by turning also

absorb the road shocks.

Essential Requirement of Wheel

In an automobile essential requirement of wheels are as

follows–

1. Strong enough to take the weight of vehicle.

2. Flexible to absorb the road shocks.

3. Perfectly balanced statically as well as dynamically.

4. Able to grip the road surface.

5. Mounted or remove easily.

6. Not too expensive.

7. Lightest possible so that the unsprang weight is least.

Classification of Wheel

The automobile wheels are generally three types:-

(i) Pressed steel disc wheels.

(ii) Wire wheels.

(iii) Light alloy casting wheels.

(i) Pressed steel disc wheels:-

Its consists of a steel rim & a

pressed steel disc. The rim is rolled section, sometime riveted

but usually welded to the flange of the disc. The disc

perform the function of spokes. The wheel assembly bolted

to the brake drum.

The Pressed steel wheels have the following advantages:-

1. Simple & robust in construction.

2. Easy to produced in large number at low cost.

3. Required negligible requirement.

4. Ease to cleaning.

2. Wire Wheels:-

Wire wheels, wire-spoke wheels, tension-spoke wheels,

or "suspension" wheels are wheels whose rims connect to

their hubs by wire spokes

Wire wheels are used on most bicycles and are still used on

many motorcycles. They were invented by aeronautical

engineer George Cayley in 1808. The first patent for wire

wheels was issued to Theodore Jones of London, England on

October 11, 1826.

The wire wheel consists of separate hub connected to the

rim with a number of spokes or wires. The headed inner end

of the spokes fit in the hub holes & the threaded outer end fit

in the rim holes, where mushroom-headed tubular nuts are

screwed through the rim holes to tighten the hub.

3. Light alloy casting wheels:-

The light alloy cast or forged wheels is the most recent type,

whose use in ever increasing both road & sports cars. Its

generally use light alloy (aluminum & magnesium alloys)

which makes it possible to use wider rims, low aspect ratio,

thus improving good adhesion, especially on corners.

The light alloy casting wheels have following advantages:-

1. Light in weight.

2. Light alloy being good heat conductors dissipate heat

produced by tyres & brake more efficiently than steel.

3. Heavier section can be used which improve the wheel

stiffness & better stress distribution is obtained.

Tyre

“A tyre is a cushion provided with an automobile wheel. Its consists

of mainly the outer cover i.e., the tyre proper & tube inside.”

The tyre-tube assembly mounted over the wheel rim. The air

inside the tube carries the entire load & provide the cushion.

The tyres are final contact between the road & the vehicle.

They take all the load of the vehicle. They are flexible &

absorb most of the shocks when a car moving on rough

roads. The surface of the tyre has certain patterns which

enable it to grip the road & provide good traction.

Function of Tyre

A Tyre perform the following functions:-

1. Support the load of the vehicle.

2. Provide cushion against shocks.

3. Transmits driving & braking force to the road.

4. Provides cornering power for smooth steering.

Requirements of Tyre

Some important requirements of good Tyre are :-

1. To be strong enough to carry load & resists damage.

2. To provide a comfortable ride to the motorists.

3. To provide good road grip for traction, cornering,

acceleration & braking.

4. To provide quite running.

5. To have along life.

6. To be economical.

7. To be flexible to cushion all shocks & impacts at least

partly.

Construction of Tyre

The lower portion on both sides has a set of steel wire

called “Bead wire”. These wires house tyre snugly in rim

& also don’t allow it come out even in the event of tyre

burst. The bead wire are surrounded by the “Bead core & plies of

canvass”. These days, instead of canvass Rayon or Nylon is

used to give more strength. On the tyre side walls as on plies rubbers vulcanized

which protects the plies from injuries due to pebbles. The top portion is called “Tread”

as it come contact with

the road & is subjected to wear. As such its made thicker. The “Breakers” are rubber covered cords similar to plies.

The job of breaker is to distributes road shocks &

prevents separation of tread from tyre. The “Cushion” is soft heat resistance rubber, which

absorbs road shocks & also bind plies & breaker together. The “Cord plies” give strength to resists internal

pressure to support load & road shocks.

Types of Tyres

1. Based on carcass Materials

1. Nylon Tyres

2. Steel Belted Tyres

3. Polyester Belted Tyres

4. Rayon's Tyres

2. Based on the Construction

1. Cross Ply Tyres

2. Radial Tyres

3. Belted Bias Tyres

3. Based on the tube

1. Conventional tubed Tyres

2. Tubeless Tyres

4. Based on the load

1. Light Load tyres

2. Heavy Load tyres

3. Other types tyres

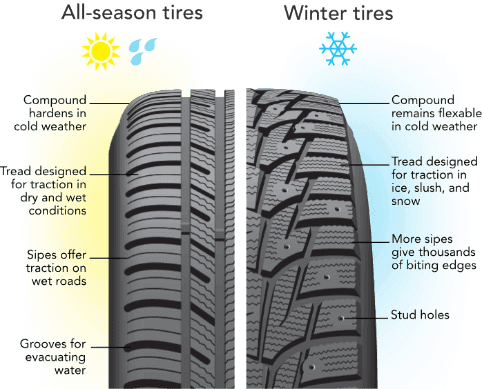

5. Based on the Session

1. Summer Tyres

2. Winter Tyres

3. All Seasons Tyres

6. Based on pattern design

1. Lug Pattern Tyres

2. Rib Pattern Tyres

3. Semi-Lug Pattern Tyres

Based on the Construction

1. Conventional Tubed Tyre:-

In the conventional tubed tyre outer portion of the tyre which rolls on the road made of synthetic rubber & its called “tread”. The tyre enclosed a tube in which air is forced to high pressure as a cushioning medium. A valve stem is attached to the tube for inflating or deflecting the same. In order to prevent the tyre from being thrown off the rim, the plies(formed from rayon cords) are attached to two rings of high tension steel wires. These rings are made to fit snugly against the wheel rim thereby anchoring the tyre to the rim. These rings are called “Beads”.

2. Tubeless Tyre:-

This type of tyre does not enclosed a tube, instead the air under pressure is filled in the tyre itself for which purpose a non return valve is fitted to the rim. The inner construction of the tyre is almost same as that of tube tyre, expect that its lined with a special air retaining liner made up of halogenated butyl rubber (e.g. Chlorobutyle or bromobutyl) for better air permeability together with heat & weather resistance. A tubeless tyre retains air for a longer period even after being punctured by nails, providing the nails remains in the tyre. Also, any hole in the tubeless tyre can be repaired simply by rubber plugging.

Based on the load & Based on the Session

1. Light–medium duty tyres:-

Light-duty tires for passenger vehicles carry loads in the range of 550 to 1,100 pounds (250 to 500 kg) on the drive wheel. Light-to-medium duty trucks and vans carry loads in the range of 1,100 to 3,300 pounds (500 to 1,500 kg) on the drive wheel.

1. Summer Tyres- Summer tyres provide better all-round performance in the warmer months. They have a relatively hard compound which softens in milder temperatures to be able to adapt to dry as well as wet roads.

Summer tyres have fewer sipes than winter tyres, but have specially designed tread bars to minimize aquaplaning. These provide more grip both longitudinally and laterally in warm temperatures. ensuring lots of grip on wet and dry roads. summer tyres have lower friction and therefore are more fuel efficient.

2. Winter Tyres - Snow tires are designed for use on snow and ice. They have a tread design with larger gaps than those on summer tires, increasing traction on snow and ice.

3. All-season Tyres - Related to snow tires are those with an M+S rating, which denotes an "all-season" capability quieter on clear roads, but less capable on snow or ice than a winter tire.

(a) All-terrain Tyres - All-terrain tires are designed to have adequate traction off road, yet have benign handling and noise characteristics for highway driving. Such tires are rated better on snow and rain than street tires and "good" on ice, rock and sand.

(b) Mud-terrain Tyres - Mud-terrain tires have a deeper, more open tread for good grip in mud, than all-terrain tires, but perform less well on pavement.

(c) High-performance Tyres - High-performance tires are rated for speeds up to 168 miles per hour (270 km/h) and ultrahigh-performance tires are rated for speeds up to 186 miles per hour (299 km/h), but have harsher ride characteristics and durability.

Other types of light-duty automotive tires include

1. Run-flat Tyres

2. Race car Tyres.

1. Run-flat Tyres - Run-flat tires obviate the need for a spare tire, because they can be travelled on at a reduced speed in the event of a puncture, using a stiff sidewall to prevent damage to the tire rim. Vehicles without run-flat tires rely on a spare tire, which may be a compact tire, to replace a damaged tire.

2. Race-car Tyres - Race car tires come in three main categories, DOT (street-legal), slick, and rain. Race car tires are designed to maximize cornering and acceleration friction at the expense of longevity.

2. Heavy duty tyres:-

Heavy duty tires for large trucks and buses come in a variety of profiles and carry loads in the range of 4,000 to 5,500 pounds (1,800 to 2,500 kg) on the drive wheel. These are typically be mounted in tandem on the drive axle.

1. Truck Tires - Truck tires come in a variety of profiles that include "low profile" with a section height that is 70 to 45% of the tread width, "wide-base" for heavy vehicles, and a "super-single" tire that has the same total contact pressure as a dual-mounted tire combination.

2. Off road Tyres - Off-road tires are used on construction vehicles, agricultural and forestry equipment and other applications that take place on soft terrain.

3. Other types tyres:-

1. Aircraft Tyres - Most aircraft tires are designed for landing on paved surfaces and rely on their landing gear to absorb the shock of landing. Example-Boeing 777.

2. Bicycle Tyres - Bicycle tires may be designed for riding on roads or over unimproved terrain and may be mounted on vehicles with more than two wheels. There are three main types: clincher, wired and tubular.

3. Industrial Tyres- Industrial tires support such vehicles as forklifts, tractors, excavators, road rollers, and bucket loaders. Those used on smooth surfaces have a smooth tread, whereas those used on soft surfaces typically have large tread features.

4. Motorcycle Tyres-Motorcycle tire provide traction, resisting wear, absorbing surface irregularities, and allow the motorcycle to turn via counter steering. The two tires contact with the ground affect safety, braking, fuel economy, noise, and rider comfort.

1. Cross Ply Construction type:-

In this type of tyre construction the ply cord are woven at an angle 300 to 400 to the tyre axis. There are two layer which run in opposite directions. These type of tyre have better wear & road holding characteristics. These type of tyre fitted on front wheel only. These type of tyre are economical.

2. Radial Ply Construction type:-

These tyre pies running bead to bead across to the crown at right angle to the rotation. On the side wall the direction of these plies are radial. The angle between the cords varies from 180 to 220 . The number of layer of depending upon the materials used.

3. Belted Bias Ply Construction type:-

These type of tyre construction is combination of Cross ply & Radial ply tyre.

Based on pattern design

1. Rib Pattern-

The pattern has several zig-zag grooves

that run along the circumference of tyre. The rib pattern is

recommended for use in both passenger & commercial

vehicles & when the drive is to be at high speeds as on

paved surface.

With Rib pattern:-

1. Tyre rolling resistance become less

2. Noise level gets reduced

3. Inferior traction

4. Greater resistance to side slipping

2. Lug Pattern-

The pattern has grooves that run roughly

at right angles to the tyre circumference. The lugs pattern

is used for trucks when driving is on unpaved surface.

With Lug pattern:-

1. Traction is good.

2. Rolling resistance is high.

3. Resistance to tendency for side slip is less.

4. Uneven wear of tread in lugs area.

3. Semi-Lug Pattern-

The pattern design is a combination

of Rib & Lugs pattern. This pattern provide the stable

driving performance both on paved surface & unpaved

surface.

With Semi-Lug pattern:-

1. The rib pattern running along the center of tyre

minimize the side slip of tyre that imparts stability to

vehicle.

2. The driving & brake performance is improved by lug

pattern on the edge.

3. Uneven wear of tread in lugs area of tyre.

The tread pattern may further design as

1. Symmetric thread pattern- where both halves of the

thread face are exactly similar.

2. Asymmetric thread pattern- where both halves of the

thread face are dissimilar.

3. Directional thread pattern- In which design to be

installed in particular direction.

Tyre Materials

The various materials used for construction of tyres as

follows:-

Rubber used in tyre is a blend of the natural & synthetics

rubbers (Styrene butadiene rubber & poly butadiene) with

various chemicals (carbon, sulphur etc.) which improve wear

resistance, reduced friction & hysteresis.

Bronze plated high tensile steel is used for beads.

The Rayon, terylene, glass fiber or steel are used for

Cords.

The steel is used in radial tyre belt & belted-bias tyre.

The plies are made of nylon, polyester & fiber glass.

Tyre Specifications/Marking

The size of the tyre has following specifications:-

P205/65R1594H

1. The first letter designates the type of tyre

P- Passenger

LT- Light Transport (Truck)

T- Temporary i.e. spare

2. The next figure indicates the section width of inflated

tyre in mm.

3. The figure after slash/ indicates the aspect ratio(H/W) of

tyre as a percentage.

Where H= Section Height

W= Section Width

4. The next letter designates the tyre construction

R- Radial tyre

B- Belted bias-ply tyre

D- Bias ply tyre

5. The next figure indicates the diameter of wheel rim in

inch on which tyre is to fit.

6. The next figure indicates the speed rating in km/hr.

Wheel Offset

Offset refers to distance between the hub mounting surface

& wheel’s centerline. The wheel offset are three types.

1. Zero wheel offset is when the hub mounting surface is in

line with the centerline of the wheel.

2. Positive wheel offset is when the hub mounting surface is in

front (more toward the street side) of the centerline of the

wheel. Most wheels on front-wheel drive cars and newer

rear-drive vehicles have positive offset.

3. Negative offset is when the hub mounting surface is behind

the wheel centerline. “Deep dish” wheels are typically a

negative offset.

Tyre Inflation Pressure

For every tyre, inflation pressures are specified by

manufacturer. These recommended pressure should be

strictly adhered to since they help to meet the requirements

of:-

1. Good performance

2. Heat control

3. Better vehicle control

4. Comfort

5. Tread kilometer

The Incorrect pressure lead to

Overheating, unsafe steering & Rapid tyre wear.

Causes of Tyre Wear

Following cause of tyre wear are:-

1. Incorrect inflection.

2. Unequal tyres.

3. Bleeding of air in tyre.

4. Incorrect rotation of tyres.

5. Misalignment.

6. Out of balance wheel.

7. Wrong loading.

8. Overloading.

9. Toe-out.

10. Careless driving.

11. Excessive braking.

Factors Affecting Tyres Life

Following main factors affecting tyre life are:-

1. Incorrect inflection.

2. Maintenance of vehicle.

3. Manner of driving.

4. Miscellaneous factors:-.

a. Heat.

b. Road conditions.

c. Seasons.

d. Position in which tyre is fitted.

Comments

Post a Comment